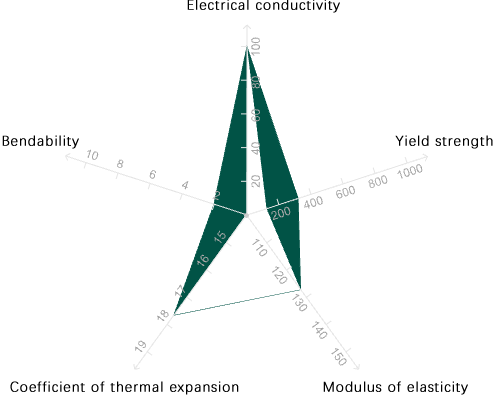

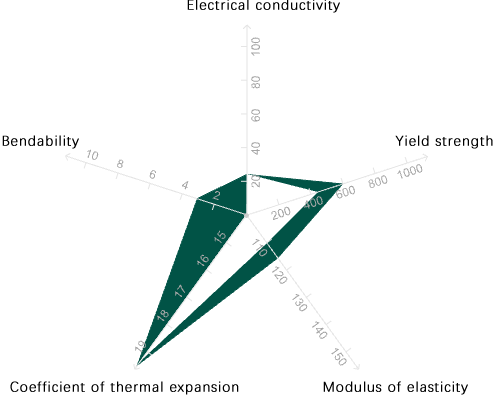

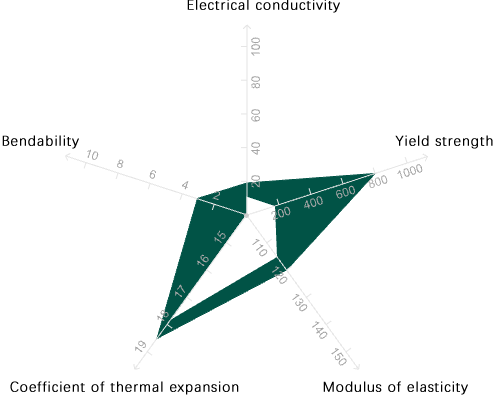

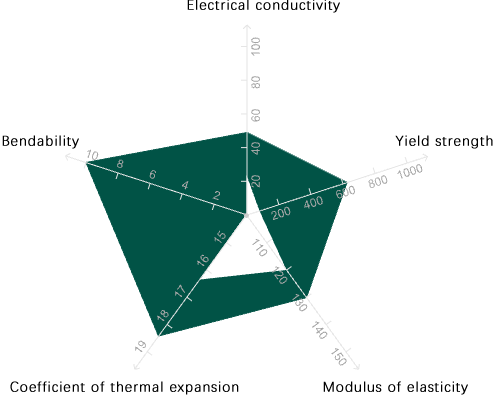

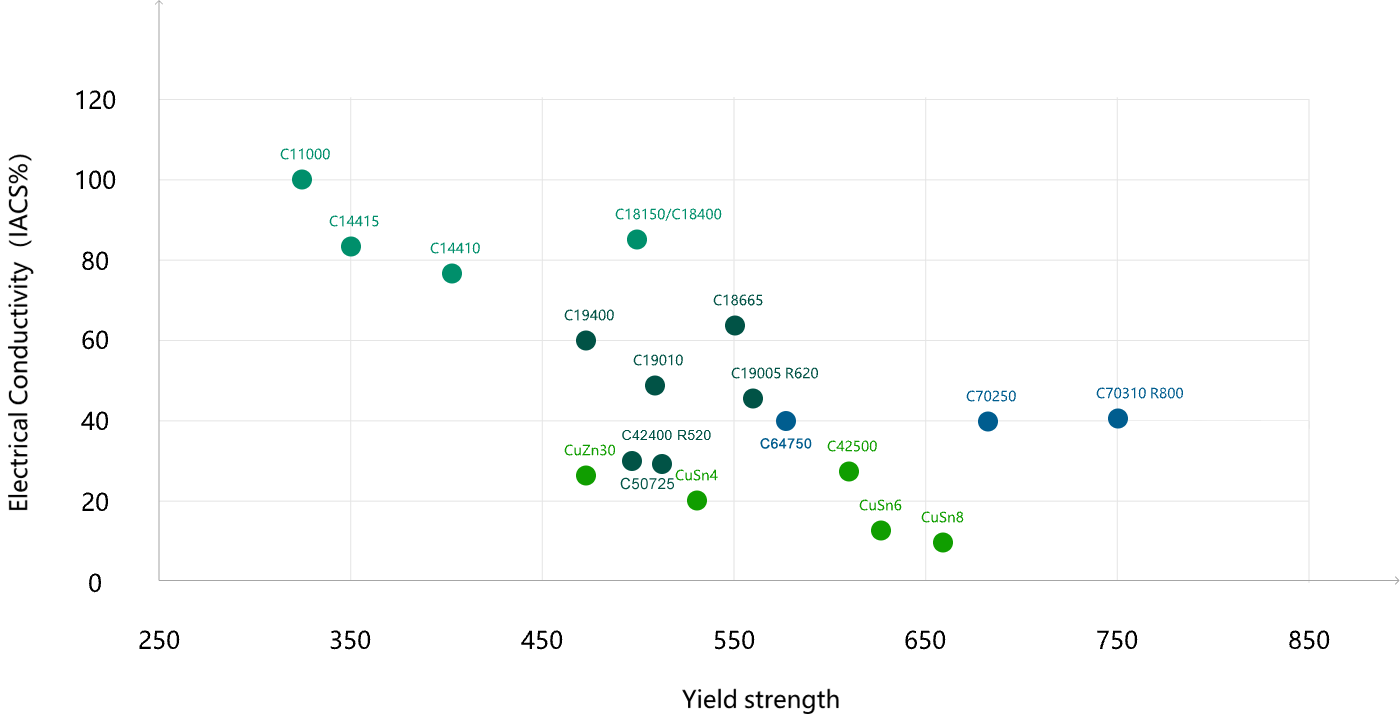

Alloy Portfolio

KMD alloys portfolio can meet various customer needs from low to high-end

Hot-dip Tinning Process

Due to stiffer reliability requirements, electro-mechanical components are increasingly made of pre-tinned strips. Above all in the automotive industry, hot-dip tinning proved to be a superior corrosion protection surface treatment.

KMD group has mature hot-dip tinning technology. We have the first HDT line and HDT patent in China. Moreover, we are exclusive producer of Sn13 and Sn28m

| Hot-dip tinning coating types | ||

|---|---|---|

| Sn10-pure tin | Sn13-thermal tin | Sn28M- tin silver |

| Coating-thickness-specifice advantages | Lowest mating and unmating forces, wear resistant | Temperature range above 130℃, improved electrical properties compared to pure tin, compatible with the new lead-free solders |

| Hot-dip tinning DIN EN 13149 (compliant with RoHS standards) | |||

|---|---|---|---|

| Thickness | Width | Coatings | Coating thickness** |

| 0.20-1.50 mm | Up to 330 mm | Pure tin, tin silver, thermal tin |

1.0-3.0 μm2.0-5.0 μm4.0-10.0 μm10.0-20.0 μm

** Coating thickness ≤ 2μm on request |

Packaging Service

We provide various supply formats for the customers to choose the most effective one for them

Pancake coils

Up to 1400mm outer diameter

Traverse-wound strip

Drums, traverse wound strips on wook, plastic or steel drums, or flangeless on cardboard or copper core.

Packaged weight: 300 - 1500 kg

Multilayer coils

Several large pancake coils are joined together by resistance welding and supplied palletised for use on pallet de-coilers. The multilayer forms on continous strip thus significantly reducing set-up time during stamping.

Availability: all KMD alloys

Standard pallet weight: 1500 kg (higher weights upon request)

Solution

We provide customers with various supply forms so that they can choose the most effective way.

Intelligent driving system

Good electrical and thermal conductivity to support the proper operation of the electronics and sensors in the system and ensure good heat dissipation.

New energy vehicles

Higher electrical conductivity and good thermal conductivity to reduce energy loss during electricity transmission and effectively dissipate heat to prevent overheating.

Communication data transmission

Excellent electrical conductivity ensures high-speed and stable signal transmission.

Smart wearable

Lightweight materials, excellent thermal performance.